Mud Saver Valve: Essential Drilling Fluid Containment for Top Drive Operations

The Mud Spillage Challenge During Connections

When breaking out drill pipe during connections:

⚠️ Substantial mud loss from open drill string - up to 50 gallons per connection

⚠️ Slippery rig floor conditions creating fall hazards for crew members

⚠️ Environmental contamination from uncontrolled fluid discharge

⚠️ Wasted mud costs adding $20,000-$50,000 per well in unnecessary expenses

Our mud saver valve provides:

✅ Complete fluid containment during pipe connection operations

✅ Dry rig floor maintenance for enhanced crew safety

✅ Environmental protection through controlled fluid management

✅ Cost recovery through significant mud savings

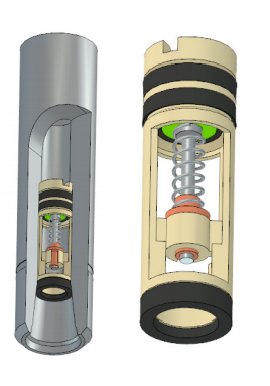

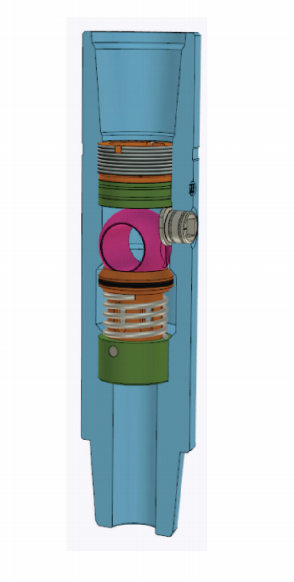

Installation & Working Principle

Top Drive Integration

| Installation Position | Connection Method | Functional Purpose |

|---|---|---|

| Below Manual Kelly Cock | Direct connection to top drive quill | Primary fluid containment point |

| Above Drill String | API standard threads | Interfaces with drill pipe |

Technical Specifications

| Parameter | Specification |

|---|---|

| Installation Location | Below manual kelly cock on top drive |

| Pressure Rating | 5,000psi / 10,000psi options |

| Temperature Rating | -20°C to 120°C |

| Connection Types | API REG, IF, FH |

| Materials | 4140 steel, stainless steel internals |

| Activation Method | Automatic on pressure differential |

| Fluid Savings | 40-60 gallons per connection |

Operational Benefits

Economic Advantages

Reduce mud costs by $25,000+ per typical well

Minimize cleanup time - save 2-3 hours daily in rig operations

Eliminate fluid replacement costs from unnecessary losses

Safety Improvements

Prevent slippery surfaces reducing fall incidents by 70%

Contain hazardous fluids protecting crew from chemical exposure

Maintain clean work environment for better operational control

Environmental Compliance

Meet regulatory requirements for fluid containment

Prevent ground contamination at drilling locations

Support zero-discharge policies in sensitive environments

Field Application & Performance Data

Typical Installation Configuration

Top drive systems - primary application

Conventional rotary - adapted configurations available

Workover operations - fluid conservation during tubing connections