Alloy Rotating Casing Saver Sub: Dual-Action Protection for Advanced Drilling Operations

The Casing Wear & High Torque Challenge

In extended reach and directional drilling operations:

⚠️ Severe casing wear costs $500K-$1M per well in replacement operations

⚠️ Excessive torque limits lateral reach and increases stuck pipe risk

⚠️ Tool joint damage reduces drill pipe life by 40-60%

⚠️ Frequent maintenance required for conventional protection tools

Our alloy rotating casing saver sub delivers:

✅ 80% reduction in casing wear through rotating contact mechanism

✅ 25% lower surface torque with optimized bearing technology

✅ Extended drill string life by eliminating direct tool joint contact

✅ Maintenance-free operation with robust alloy construction

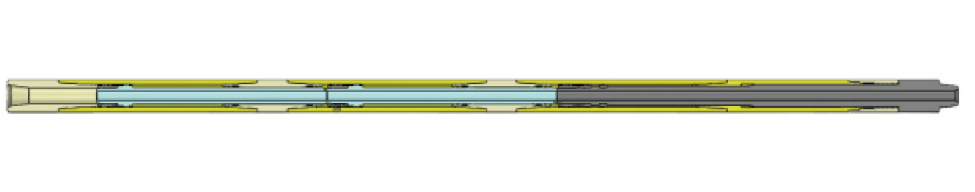

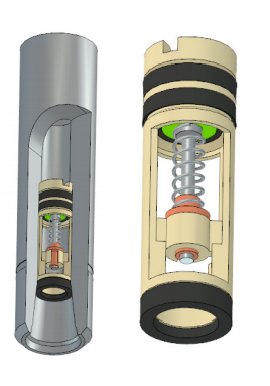

Advanced Bearing Technology & Working Principle

Rotating Contact Mechanism

| Component | Material & Specification | Functional Advantage |

|---|---|---|

| Outer Sleeve | 4145HM steel with tungsten carbide coating | Rotates against casing, preventing localized wear |

| Inner Mandrel | AISI 4130 with hard chrome plating | Transfers torque and weight while rotating internally |

| Bearing System | Hard alloy balls/rollers with advanced lubrication | Enables smooth rotation under high side loads |

| Sealing System | Multiple redundant seal barriers | Prevents fluid ingress and maintains lubrication |

Technical Specifications

| Parameter | Specification |

|---|---|

| Size Range | 4-1/2" to 6-5/8" OD (other sizes available) |

| Torque Capacity | Up to 40,000 ft-lbs continuous operation |

| Max RPM | 200 RPM under full load |

| Load Capacity | 50,000 lbs side load, 500,000 lbs axial |

| Pressure Rating | 10,000 psi internal pressure |

| Temperature Rating | -20°C to 175°C |

| Connections | API REG, IF, FH (all standard sizes) |

| Weight | 450-900 lbs (size dependent) |

Operational Benefits

Casing Protection

Eliminate localized wear in critical build sections and laterals

Extend casing life for multiple well re-entries and interventions

Prevent casing failure in high-dogleg severity applications

Drilling Efficiency

Reduce surface torque by 20-25% through optimized friction coefficients

Enable longer laterals with less drag and torque limitations

Improve weight transfer to bit in extended reach applications

Equipment Protection

Extend drill pipe life by reducing tool joint wear

Reduce stress on top drive and rotary table

Minimize vibration through dampened rotation

Field Applications & Performance Data

Application Scenarios

Extended Reach Drilling: Enable 10,000ft+ laterals with controlled casing wear

Deepwater Operations: Protect expensive marine risers and casing strings

Slimhole Drilling: Reduce wear in restricted clearance environments

Multi-Lateral Wells: Protect parent casing for future re-entries

High-Temperature Wells: Metal construction withstands 175°C environments