MWD Orientation Sub: Precision Tool Face Alignment for Directional Drilling

The Directional Drilling Alignment Challenge

Inaccurate tool face orientation causes:

⚠️ Poor wellbore placement missing target zones

⚠️ Incorrect wellbore trajectory requiring costly corrections

⚠️ MWD sensor errors from magnetic interference

⚠️ Reduced drilling efficiency from repeated orientation attempts

Our MWD orientation sub delivers:

✅ Precise tool face alignment for accurate directional control

✅ Non-magnetic properties ensuring clean MWD survey data

✅ Robust construction for reliable performance in harsh conditions

✅ API standard compliance for seamless integration

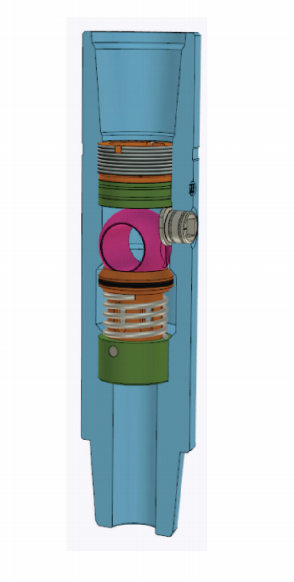

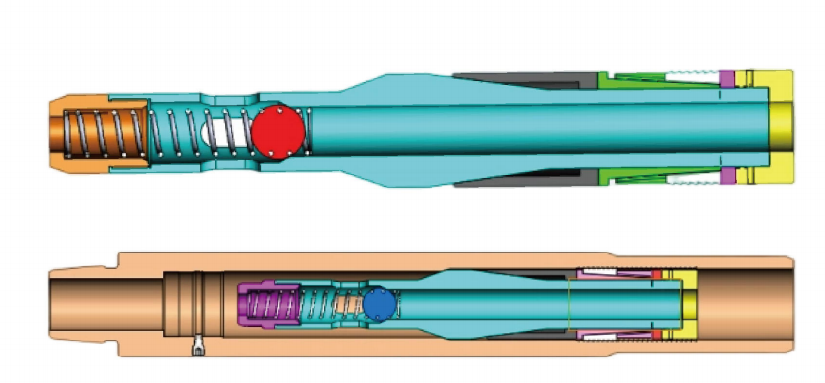

Design & Working Principle

Precision Alignment Technology

| Feature | Specification | Functional Benefit |

|---|---|---|

| Non-Magnetic Material | Austenitic stainless steel | Eliminates magnetic interference with MWD sensors |

| Precision Machining | 0.01mm tolerance | Ensures accurate tool face transmission |

| Alignment Marks | Laser-etched reference lines | Quick visual orientation verification |

| Pressure Balancing | Integrated pressure compensation | Maintains accuracy under pressure differentials |

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | 316L Stainless Steel (Non-Magnetic) |

| Magnetic Permeability | <1.005 μ |

| Pressure Rating | 10,000psi / 15,000psi / 20,000psi options |

| Temperature Rating | -20°C to 175°C |

| Connections | API REG, IF, FH (all standard sizes) |

| Length | 1.5m - 3.0m (standard and custom lengths) |

| Alignment Accuracy | ±0.5° tool face precision |

Operational Advantages

Directional Control Precision

Accurate tool face data for precise wellbore steering

Real-time orientation feedback to surface monitoring systems

Consistent performance throughout drilling operation

MWD System Integration

Seamless compatibility with all major MWD/LWD systems

Protected sensor environment from magnetic interference

Reliable data transmission through optimized internal design

Field Efficiency

Quick installation with standard connections

Minimal maintenance required during operations

Proven reliability in demanding drilling environments

Field Applications & Performance Data

Application Scenarios

Directional Wells: Precise tool face control in build and turn sections

Horizontal Laterals: Maintain accurate orientation in long lateral sections

Complex 3D Wells: Reliable steering in multi-target environments

Extended Reach Drilling: Consistent performance in high-angle wells

Performance Metrics

✅ Tool Face Accuracy: ±0.5° under full operating conditions

✅ Survey Reliability: 99.8% data accuracy in magnetic surveys

✅ Operational Uptime: 98.5% reliability in continuous operations

✅ Compatibility: 100% with industry-standard MWD systems